Aluminum Foundry: Choosing the Right Alloy for Your Project

Wiki Article

Opening the Potential of Aluminum Castings: Informative Insights and Expert Providers

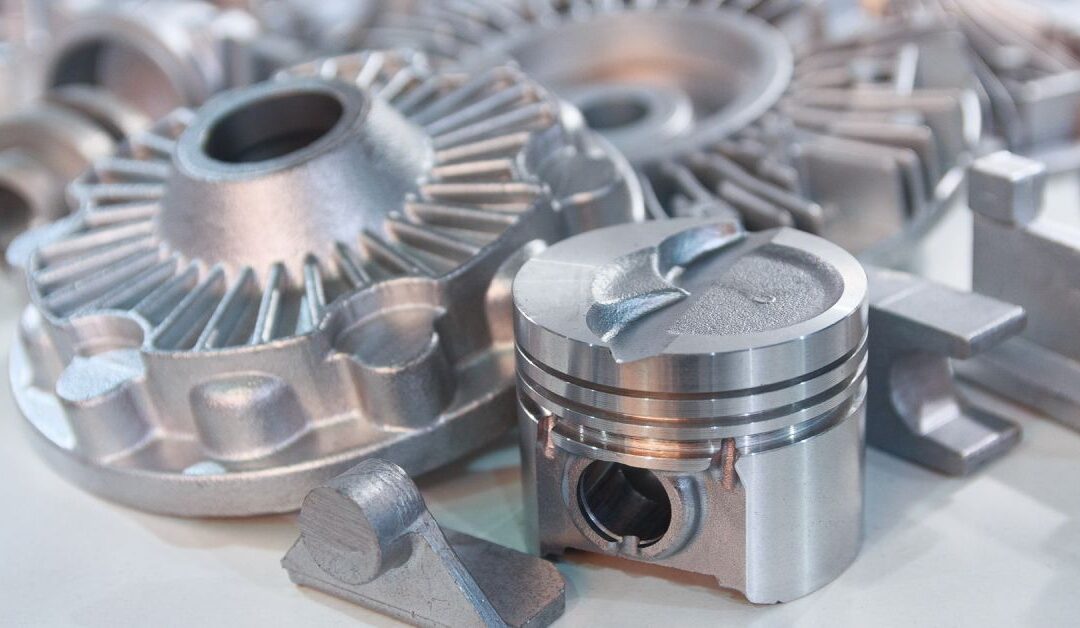

Light weight aluminum castings existing considerable benefits in different producing markets. Their corrosion-resistant and light-weight homes make them optimal for requiring applications. Innovations in casting technologies further boost their capacity. Expert solutions aid optimize layouts for maximum effectiveness and efficiency. As sectors progress, understanding these components comes to be crucial. The implications of these advancements might improve the future of production. What developments lie ahead for light weight aluminum castings?The Benefits of Aluminum Castings in Modern Production

Although numerous materials are utilized in manufacturing, aluminum spreadings stick out for their one-of-a-kind advantages. Their light-weight nature enables reduced power intake during transportation and assembly, making them an environment-friendly choice. The convenience of aluminum makes it possible for manufacturers to generate detailed layouts and complicated shapes, which can be tailored for details applications. Furthermore, light weight aluminum castings exhibit excellent rust resistance, boosting the durability of products in different atmospheres.The ability to achieve tight tolerances adds to the accuracy of ended up components, decreasing the need for substantial machining. Furthermore, aluminum's thermal conductivity makes it excellent for applications needing efficient warmth dissipation. The recyclability of light weight aluminum likewise contributes to its appeal, lining up with lasting manufacturing methods. On the whole, the advantages of aluminum castings assist in ingenious design options and contribute to affordable production procedures, placing them as a favored selection in many markets today.

Trick Feature of Aluminum That Enhance Efficiency

Light weight aluminum has a number of crucial buildings that substantially enhance its efficiency in numerous applications. Its light-weight and sturdy nature, combined with exceptional deterioration resistance, make it an excellent option for many sectors. Additionally, aluminum's superior thermal conductivity additionally contributes to its adaptability and performance in producing procedures.Long Lasting and lightweight

An amazing combination of resilient and lightweight qualities makes light weight aluminum a perfect product for numerous applications. This distinct home permits makers to create parts that lower total weight without compromising toughness. The reduced density of light weight aluminum contributes to enhanced fuel efficiency in auto and aerospace sectors, where light-weight building is vital. Furthermore, its resilience assurances longevity and dependability popular settings, making it ideal for items ranging from consumer electronics to industrial equipment. The ability of aluminum to endure mechanical stress and anxieties while continuing to be light causes ingenious styles and boosted performance throughout various industries. On the whole, light weight aluminum's light-weight and long lasting nature substantially enhances its charm, driving innovations in technology and design services.Corrosion Resistance Perks

The remarkable light-weight and long lasting residential properties of aluminum are complemented by its remarkable deterioration resistance, making it an extremely beneficial material across different industries. This resistance is largely connected to the development of a protective oxide layer that naturally creates on its surface area. This layer serves as a barrier, avoiding moisture and various other destructive agents from permeating the steel. Aluminum castings display improved longevity, reducing the need for frequent substitutes or fixings. Industries such as vehicle, aerospace, and aquatic considerably take advantage of this residential property, as it adds to the general performance and integrity of their items. By minimizing corrosion-related failings, aluminum spreadings assure reduced maintenance costs and boosted security, additional strengthening aluminum's function as a preferred product sought after environments.Outstanding Thermal Conductivity

One of the standout functions of light weight aluminum is its outstanding thermal conductivity, which greatly boosts the performance of various applications. This building allows aluminum to successfully transfer warmth, making it perfect for elements in vehicle, aerospace, and digital markets. The capacity to dissipate heat successfully lessens the threat of getting too hot, therefore enhancing the durability and dependability of items. Wisconsin Aluminum Foundry. Additionally, aluminum's light-weight nature combined with its thermal effectiveness adds to power savings in heating and cooling down systems. The combination of these characteristics positions aluminum spreadings as a superior option for suppliers seeking efficiency and effectiveness. As industries increasingly focus on lasting methods, aluminum's thermal conductivity also plays a critical function in enhancing power usage and lowering ecological influenceAdvancements in Aluminum Spreading Technologies

As sectors proceed to look for lighter and more reliable materials, developments in aluminum casting innovations are arising to satisfy these needs. Advancements in 3D printing and additive production have actually allowed the manufacturing of complicated geometries that were impossible or previously challenging to achieve. These techniques lower product waste and enable rapid prototyping, greatly shortening advancement cycles.Additionally, the intro of innovative alloys and warm treatment procedures has actually enhanced the mechanical homes of aluminum castings, making them appropriate for demanding applications in automotive and aerospace fields. Techniques such as vacuum cleaner spreading and die casting have actually improved the high quality and uniformity of actors items, enhancing and decreasing flaws performance.

Furthermore, automation and expert system are being incorporated into the casting process, promoting real-time monitoring and control, which guarantees greater precision and performance. These innovations collectively position light weight aluminum casting as a forward-thinking option for sectors intending for sustainability and performance.

Crucial Services for Optimizing Light Weight Aluminum Castings

To accomplish excellent performance in aluminum castings, numerous necessary solutions play a vital duty. Design optimization methods, quality control procedures, and finishing and coating choices are key elements that can greatly enhance the last item. Understanding and carrying out these services can lead to boosted sturdiness and performance of aluminum spreadings.Layout Optimization Methods

Reliable layout optimization methods are important for boosting the performance and performance of light weight aluminum spreadings. These methods entail a systematic approach to fine-tuning the geometry and specifications of actors parts. By leveraging computer-aided design (CAD) software program, engineers can mimic numerous layout scenarios to identify the most efficient shapes and structures. In addition, finite component evaluation (FEA) is made use of to anticipate how layouts will certainly behave under stress, permitting adjustments that enhance sturdiness while decreasing product usage. Incorporating layout for manufacturability (DFM) principles warranties that the spreading process is structured, decreasing manufacturing prices and lead times. Eventually, these optimization approaches add to improved mechanical residential or commercial properties and total product high quality, paving the way for enhanced functionality in different applications.

Quality Control Processes

Quality guarantee processes play an important role in the optimization of aluminum castings, making sure that each element fulfills rigorous efficiency and durability standards. These procedures typically encompass rigorous inspection procedures, including dimensional checks, metallurgical evaluation, and non-destructive screening approaches. By employing advanced innovations such as ultrasonic testing and X-ray inspection, producers can determine prospective issues early in the production cycle. Additionally, adherence to market standards, such as ISO accreditations, Aluminum Castings enhances reliability and dependability in the last products. Constant surveillance and responses loops help refine production techniques, even more improving quality. Ultimately, effective quality control not just minimizes waste and rework yet likewise makes the most of client contentment by delivering light weight aluminum spreadings that perform consistently under demanding conditions.Completing and Finishing Options

Ending up and finish choices are important for boosting the efficiency and longevity of light weight aluminum spreadings. Various strategies, such as anodizing, powder finishing, and paint, can considerably improve corrosion resistance and aesthetic allure. Plating rises surface solidity and improves resistance to put on, while powder finish supplies a colorful and resilient coating that endures harsh settings. Additionally, paint offers versatility in style yet may call for more regular upkeep. The choice of ending up technique depends on the designated application, ecological exposure, and preferred look. Correct surface area preparation and application strategies are essential to accomplishing ideal results. By choosing proper ending up and finish choices, makers can assure that light weight aluminum spreadings not only meet practical needs but likewise keep their aesthetic integrity with time.Applications of Light Weight Aluminum Castings Across Industries

Aluminum castings play a crucial function in different industries, showcasing their versatility and flexibility across multiple applications. In the auto market, aluminum spreadings are made use of for engine parts, transmission real estates, and wheels, adding to lightweight frameworks that boost fuel performance. The aerospace industry gain from aluminum castings in critical parts, such as aircraft frames and engine elements, where strength-to-weight ratios are vital.The electrical and electronics markets utilize aluminum spreadings for housings and warm sinks, guaranteeing effective thermal administration. In the building and construction industry, aluminum castings are used in building elements and structural components, supplying both aesthetic appeal and sturdiness. In addition, customer goods usually feature light weight aluminum castings in things like kitchenware and appliances, highlighting their usefulness and simplicity of production. On the whole, the diverse applications of aluminum castings underline their relevance in driving development and efficiency throughout countless areas.

Future Trends in Light Weight Aluminum Casting Solutions

As industries progressively focus on sustainability and efficiency, future patterns in light weight aluminum casting options are anticipated to concentrate on innovative manufacturing methods and cutting-edge materials. Aluminum Castings. One significant trend is the adoption of additive manufacturing, which permits intricate geometries and decreased waste, boosting the overall efficiency of production. In addition, the integration of clever technologies, such as IoT and AI, is expected to optimize the spreading procedure, enabling real-time surveillance and predictive maintenanceSustainable techniques will likewise acquire importance, with a focus on recycling aluminum and using green ingredients. Additionally, the development of lightweight alloys will assist in the production of more powerful, much more long lasting components that satisfy the demands of different industries, including automotive and aerospace. As r & d remain to advance, these fads will likely redefine light weight aluminum casting, positioning it as an essential player in the shift toward a more sustainable production landscape.

Often Asked Inquiries

Just How Do Light Weight Aluminum Castings Compare to Other Products in Price?

Light weight aluminum spreadings normally provide a competitive expense contrasted to products like steel and titanium, especially in lightweight applications. Their price, integrated with desirable homes, makes them a preferred choice in various markets for economical remedies.

What Prevail Defects in Aluminum Castings and Exactly How to Stop Them?

Usual issues in light weight aluminum spreadings include contraction, surface area, and porosity flaws. Stopping these problems includes careful control of putting temperature levels, correct mold and mildew design, and complete high quality inspections throughout the casting process to ensure suitable outcomes.Can Light Weight Aluminum Castings Be Recycled, and Exactly How Does It Influence the Setting?

Aluminum castings can be reused successfully, substantially lowering ecological effect. Recycling preserves power, decreases greenhouse gas exhausts, and decreases garbage dump waste, adding to a much more sustainable cycle of material use within markets and advertising environmentally friendly techniques.What Is the Typical Preparation for Aluminum Spreading Projects?

The normal preparation for aluminum casting jobs ranges from 2 to six weeks, depending on variables such as tooling, intricacy, and quantity requirements. Efficient planning can substantially decrease this duration while making sure quality results.How Can I Choose the Right Light Weight Aluminum Alloy for My Details Application?

Choosing the ideal light weight aluminum alloy includes reviewing mechanical buildings, corrosion resistance, and thermal conductivity. Consulting product specifications and comprehending application demands, along with expert assistance, can substantially help in making an educated choice.Furthermore, the intro of innovative alloys and heat treatment processes has improved the mechanical properties of light weight aluminum castings, making them appropriate for demanding applications in aerospace and vehicle sectors. Efficient layout optimization techniques are crucial for improving the efficiency and performance of light weight aluminum castings. Completing and finishing alternatives are essential for improving the efficiency and durability of aluminum spreadings. Aluminum spreadings play an important role in various sectors, showcasing their convenience and adaptability across numerous applications. In the automotive field, light weight aluminum castings are used for engine elements, transmission housings, and wheels, adding to light-weight frameworks that improve gas efficiency.

Report this wiki page